Gas fired infrared heating appliances are available from a variety of manufacturers, each with their own design nuances and performance claims. Although many factors of the design influence radiant performance of the heater, one of the most critical considerations is the reflector design. This article outlines the reflector as a component for maximum performance as found in Superior Radiant Products (SRP) heating equipment.

Reflector Function

The function of the reflector as a component on an infrared heater is two-fold:

1. To redirect as much radiant energy as possible into the space after it leaves the heat exchanger tube – to do this in the most efficient manner possible, the energy should not “rattle around” under the reflector, repeatedly bouncing between the tube and reflector, but rather should bounce off the reflector and then leave the appliance; and

2. Trap air near the heat exchanger, to prevent a flow of air from “cooling” the tube temperatures, and hence de-creasing the radiant output from the tube. As an example, if a 1000°F tube is cooled just 10% to 900°F, the loss in radiant output is approximately 25%! Higher tube temperatures produce a larger percentage of radiant energy (versus convected energy).

Competition Falls Short

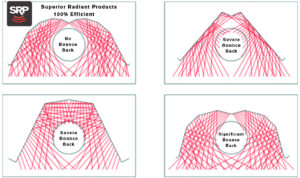

SRP’s reflector directs nearly 100% of all energy from the tube into the space, and is the most efficient reflector in the industry. We have incorporated materials that have high emissivity and utilize 10 reflective surfaces at critically controlled angles to accomplish this. Additionally, our reflector extends completely below the bottom of the tube.

Figure 1 Reflector Efficiency Comparison

Together with a full profile end cap on the reflector, our reflector system minimizes the convective loss from the heat exchanger by trapping as much heated air around the tubing as possible. This “deep dish” design is critical for proper performance of the heater.

For comparison purposes, the diagrams in Figure 1 on the previous page clearly show the advantage of SRP’s reflector design as compared to popular competition models.

What About Insulation?

In recent years, some competitors have begun insulating their reflectors. These more expensive configurations can help reduce the overall convective loss from the reflector material by reducing the temperature of the surface subject to convective heat exchange, but they do nothing to improve the “bounce back” deficiencies as discussed and illustrated above. This is because infrared energy responds to all the same optical mechanisms as other forms of electromagnetic energy, making the physical shape and the inherent material properties (reflectivity) of the reflector most important in determining how efficiently radiated energy leaves the appliance and is directed into the space.

Insulating the reflector also does very little to improve the amount of “dead air” space that surrounds the tubing; this is a function of the “deep dish” nature of the reflector design, and the use of end caps etc. to prevent the air warmed by the tube from spilling into the space.

On a properly designed “deep dish” infrared reflector system, such as used by SRP, the amount of convection loss directly from the reflector is very small (estimated to be between 1 and 3% of the total input of the appliance, depending on firing rate). Reducing this small amount by even 25% is virtually insignificant. These small changes DO NOT affect the radiant output of the tube – as the tube temperatures are determined by design to be as high as practical, and as allowed by the appliance approval standard. It is the marriage of the burner, tube and reflector system (“fixture efficiency”) that ultimately determines how much useable radiant energy leaves the appliance. As an illustration of this, radiant factor testing according to EN-419-2 has shown SRP’s standard reflector system to be >5% more effective than competitive insulated reflectors and >44% more effective than the same competitor’s uninsulated reflector.

What About Surface Finish?

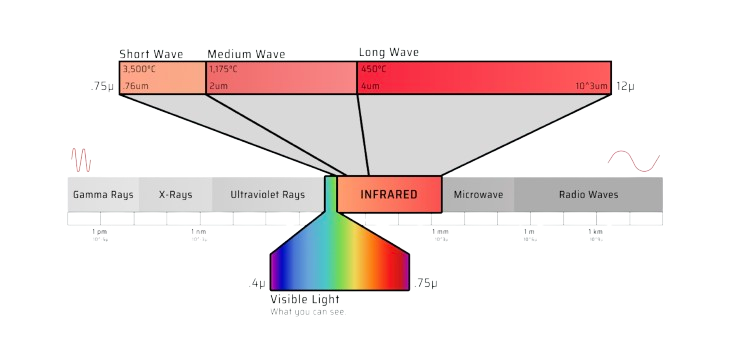

Additionally, some competitors argue for “polished” surfaces as an improvement over “mill finished” surfaces. Polished surfaces may have an effect on visible light, but they do not improve the reflectivity of a reflector versus “mill finished” surfaces for infrared wavelength energy. Overall reflectivity of the material is what matters and SRP utilizes aluminum, which has very high reflective properties.

In summary, the SRP reflector system incorporates highly reflective materials in a superior “deep dish” design configuration to release ~100% of the radiant energy produced by the tube to the space, while minimizing convective losses. This combination of technological innovations results in SRP heaters with radiant outputs (percentage of input energy converted to radiant energy and released to the space) comparable, and in many cases, superior to any tube heater in the market.